Metal injection molding (MIM) is an innovative manufacturing process that produces complex parts with great precision. It has been gaining popularity among manufacturers in a variety of industries due to its cost-effectiveness, design flexibility, and overall high quality. In this article, we will discuss what metal injection molding is, how it works, the advantages of using it for producing parts, and some of the most common applications.

Metal Injection Molding

Metal injection molding (MIM) is a manufacturing technology that involves blending metal powders with thermoplastic binders to create a feedstock. The feedstock is then injected into a mold cavity under high pressure and heated to remove the binder, leaving behind a compacted metal part. This process enables manufacturers to produce complex metal parts with tight tolerances and intricate geometries at a lower cost than traditional machining methods.

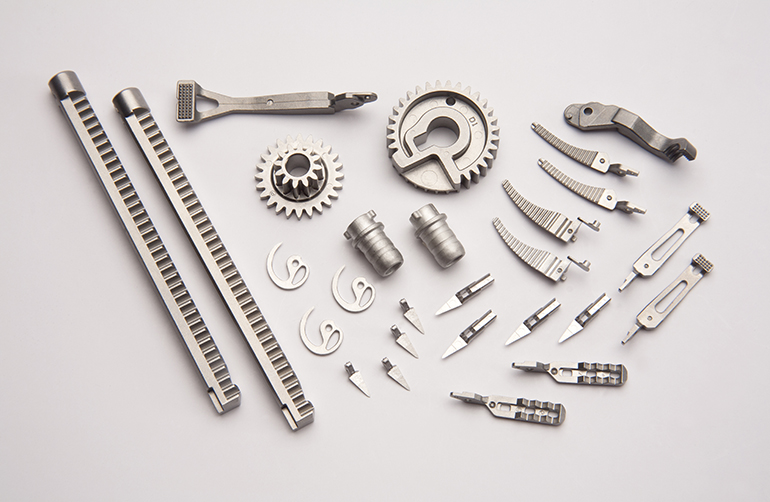

MIM parts are commonly used in various industries, including automotive, aerospace, medical devices, electronics and consumer goods. These parts offer exceptional mechanical properties such as high strength, hardness and wear resistance. They also exhibit excellent corrosion resistance and can withstand extreme temperatures.

Metal injection molding offers several advantages over other manufacturing technologies such as investment casting or CNC machining. It allows for greater design freedom, shorter lead times and reduced material waste. As MIM continues to evolve and become more widely adopted by businesses worldwide, it has the potential to revolutionize the production of small precision components for many applications.

Benefits of MIM Parts

Metal injection molding (MIM) is a manufacturing process that uses the combination of metal powder and binders to create complex parts. MIM parts offer several benefits, including high accuracy, repeatability, and consistency. Because of their high precision and uniformity, MIM parts are often used in industries such as aerospace, medical technology, automotive engineering, and consumer electronics.

Another benefit of MIM parts is their ability to produce complex shapes with intricate geometries. This makes them ideal for creating small mechanical components with tight tolerances. Additionally, MIM parts can be produced at high volumes while maintaining excellent dimensional stability and surface finish quality.

Finally, MIM parts offer cost advantages over other production methods such as machining or casting. The process allows for increased material utilization due to less waste generation which yields lower costs per part.

Design Considerations for MIM Parts

Metal injection molding (MIM) parts are becoming increasingly popular in many industries due to their high strength, durability, and complex geometries. However, designing MIM parts requires careful consideration of several factors that can impact the final product’s quality and performance.

One critical design consideration is material selection. While MIM can work with various metals, some may require additional steps or cause issues during processing. Choosing the right material for a specific application can ensure optimal properties such as strength or corrosion resistance.

Another crucial factor is part geometry. The intricate shapes achievable with MIM allow for unique designs but also pose challenges during production. Designers must consider factors such as wall thickness and draft angles to prevent defects like warping or cracking.

Finally, designers must account for post-processing requirements like sintering or surface finishing when creating MIM parts. These steps play a vital role in achieving the desired properties of the finished part while maintaining dimensional accuracy.

Overall, understanding these design considerations is essential to produce high-quality MIM parts that meet performance specifications while optimizing production efficiency and cost-effectiveness.

Applications of MIM Parts

Metal injection molding (MIM) is a manufacturing process that produces complex metal parts from fine metal powders. MIM combines the benefits of plastic injection molding with the strength and durability of metals, making it ideal for producing small, intricate parts. The MIM process begins with mixing powdered metals with a binder material to create a feedstock, which is then injected into a mold where it is heated and solidified.

The applications of MIM parts are vast and varied, ranging from automotive to medical devices. In the automotive industry, MIM parts are used in engine components such as gears and bearings, as well as in fuel injection systems. MIM parts are also commonly used in firearms for components like triggers and hammers due to their strength and precision.

In the medical field, MIM parts are used in surgical tools such as forceps and scissors, as well as implantable devices like bone screws and dental implants. The ability to produce complex shapes with high accuracy makes MIM an attractive option for medical device manufacturers seeking reliable production methods for small-scale manufacturing.

Materials Used in MIM Parts

Metal injection molding (MIM) is a manufacturing process that combines the design flexibility of plastic injection molding with the strength and durability of metal. MIM parts are manufactured by mixing fine metal powders with a binding agent to create a feedstock material. The feedstock is then injected into a mold, where it solidifies and forms the desired shape.

The materials used in MIM parts can vary depending on the application requirements, but typically include metals such as stainless steel, titanium, copper, iron, and nickel alloys. These materials offer high strength-to-weight ratios, excellent wear resistance, and good corrosion resistance.

In addition to metals, other materials may also be used in MIM parts. For example, ceramic powders can be added to provide additional strength or improve heat resistance. Additionally, polymers may be used as binders or additives to improve flow properties or enhance surface finish. Overall, the wide range of materials available for use in MIM parts makes this process an attractive option for manufacturers looking for versatile and cost-effective production solutions.

Production Process of MIM Parts

Metal injection molding parts (MIM) are used in various applications, including automotive, medical devices, aerospace, and electronics. The production process of MIM parts involves several stages. Firstly, metal powders are mixed with a binder material to create a feedstock. This mixture is then injected into a mold cavity using high pressure.

After injecting the feedstock into the mold cavity, it undergoes debinding where the binder material is removed from the part through heat treatment or solvent extraction. The resulting part is then sintered at high temperatures to achieve its final density and strength.

The MIM process offers several benefits such as complex geometries, tight tolerances, and cost-effective mass production compared to traditional manufacturing methods like CNC machining or casting. As technology continues to improve in materials science and 3D printing techniques related to MIM processes will continue to advance making it an attractive alternative for producing small intricate parts at scale across various industries.

Conclusion: Advantages of MIM

Metal injection molding (MIM) is a manufacturing process that combines the versatility of plastic injection molding with the strength and durability of metal. MIM parts are made by mixing finely powdered metals with a binder material to create a feedstock, which is then injected into a mold cavity under high pressure. After the injection, the parts are debound and sintered to remove the binder and fuse the metal particles together.

One advantage of MIM is its ability to produce complex shapes with high precision and consistency. This makes it ideal for small, intricate components that require tight tolerances, such as gears, connectors, and medical implants. MIM also offers design flexibility, allowing engineers to incorporate multiple features into a single part or combine different metals for optimal performance.

Another advantage of MIM is its cost-effectiveness compared to traditional machining methods like CNC milling or investment casting. With MIM, there’s less material waste since only as much powder as necessary is used for each part. Additionally, because MIM can produce multiple parts in one cycle, it saves time and reduces labor costs associated with post-processing operations like assembly or welding. Overall, these advantages make MIM an attractive option for manufacturers looking to boost efficiency while maintaining quality standards.